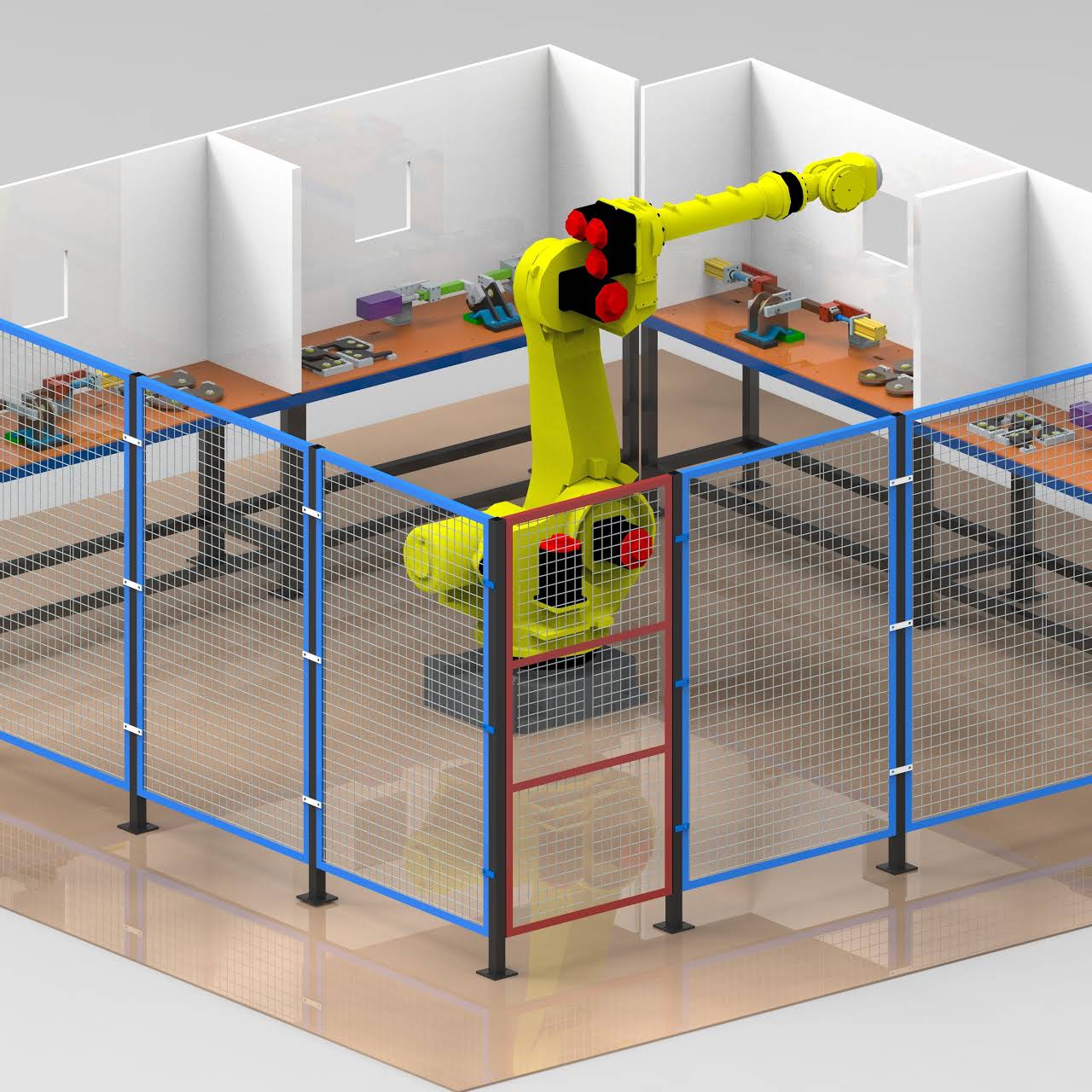

Robotic Welding

With the use of pneumatic actuators and perfect clamping the complicated process of welding fixture is made simple.

This not only increases accuracy but also increases productivity, repeatability and improves efficiency.

Fixturing

Successfully designed a robotic welding fixture for a component which is assembled on the heavy duty truck chassis.

Adjustable shim packs for maintaining the allowed tolerances. Fully constrained clamping using Pneumatic and manual clamps.

Appropriate use of supports which provide perfect contact with the clamping parts.

The fixture is designed such that the parts which do not fit in the defined tolerances can be easily sorted out and rejected at the same point.

Any unskilled worker can easily operate the process as the system is in a closed loop and generates feedback at each and every stage of operation.